Global Condition Monitoring System Market Set to Reach USD 9,196.7 Million by 2035, Surging at 7.7% CAGR, Driven by Increasing Industrial Demand | Future Market Insights, Inc.

Germany is expected to be an attractive market throughout the forecast period. According to the study, Germany is expected to account for almost one-fifth of the European market through 2035. The U.S. is predicted to remain one of the most attractive markets during the forecast period according to Future Market Insights analysis. According to the study, the U.S. is expected to account for over 80% of the North America market through 2035.

/EIN News/ -- NEWARK, Del, Feb. 17, 2025 (GLOBE NEWSWIRE) -- According to a Future Market Insights (FMI), the global condition monitoring system market is poised for significant growth, expanding from USD 4,380.0 Million in 2025 to USD 9,196.7 Million by 2035, reflecting a 7.7% CAGR during the forecast period. As industries increasingly adopt predictive maintenance strategies, the demand for condition monitoring systems is rising across manufacturing, energy, transportation, and other sectors.

Condition monitoring systems are essential for minimizing unplanned downtime, optimizing maintenance schedules, and reducing operational costs. With the advancement of IoT, AI, and data analytics, companies are integrating smart monitoring solutions to enhance equipment reliability and improve overall operational efficiency.

Experience Our Expertise With A Sample Report - Request Yours Now! https://www.futuremarketinsights.com/report-sample#5245502d47422d31303436

Market Forecast and Growth Drivers:

The Condition Monitoring System Market is expected to maintain a robust growth trajectory due to several key factors:

- Industry 4.0 and Smart Manufacturing: The rise of automated and connected manufacturing facilities is fueling the demand for real-time condition monitoring systems that can detect faults before they lead to costly failures.

- Energy Sector Expansion: With the increasing adoption of renewable energy sources such as wind and solar power, there is a heightened need for monitoring solutions that ensure the reliability of critical assets like turbines and generators.

- Transportation & Logistics Growth: In industries such as aviation, railways, and marine, condition monitoring plays a vital role in ensuring safety, reducing maintenance costs, and enhancing fleet performance.

- Advancements in Sensor Technology: The development of wireless and AI-powered sensors has significantly improved the accuracy and efficiency of condition monitoring, making predictive maintenance more accessible.

Best-Growing Segments:

Vibration Monitoring to Dominate the Market

Among various condition monitoring techniques, vibration monitoring is expected to witness the highest demand due to its ability to detect early signs of mechanical failures. This technique is widely used in industrial machinery, automotive, and aerospace applications, where continuous operation is crucial.

Key Factors Driving Vibration Monitoring Growth:

- Ability to detect mechanical imbalances, misalignments, and wear & tear

- Increasing use in rotating machinery like motors, pumps, and turbines

- Integration with AI-driven predictive maintenance platforms

Remote Monitoring Gaining Traction

The demand for remote condition monitoring solutions is rapidly increasing, particularly in industries where physical inspections are challenging. Cloud-based monitoring systems are gaining popularity as they enable real-time data collection and analysis from multiple locations, reducing the need for on-site personnel.

Regional Outlook:

United States: Expanding Adoption Across Industries

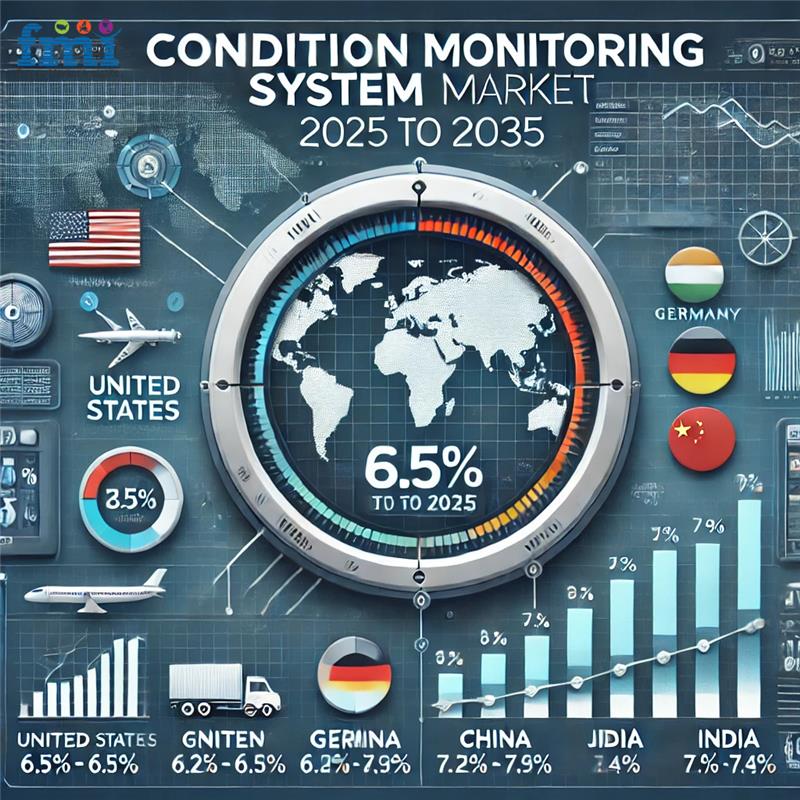

The United States is expected to grow at a 6.5% CAGR during the forecast period. The country is witnessing increased investment in industrial automation, oil & gas, and aerospace sectors, where condition monitoring plays a crucial role in ensuring efficiency and safety. The presence of major industry players, along with government initiatives promoting smart manufacturing, is further propelling market growth.

Germany: Driving Growth Through Industrial Innovation

Germany’s market is projected to expand at a 6.2% CAGR, driven by its strong presence in automotive, heavy machinery, and industrial automation sectors. The country’s emphasis on Industry 4.0 and smart manufacturing solutions has accelerated the adoption of advanced condition monitoring technologies.

China: Fast-Paced Industrial Expansion

With a 7.1% CAGR, China is one of the fastest-growing markets for condition monitoring systems. Rapid industrialization, government investments in smart factories, and the growing need for predictive maintenance solutions are key factors contributing to market growth. The country’s expanding automotive, energy, and manufacturing sectors are significantly boosting demand.

Japan: Focus on Reliability and Efficiency

Japan’s market is projected to grow at a 5.9% CAGR, fueled by the country’s focus on precision engineering and automation. With a strong industrial base and increasing adoption of AI-based condition monitoring solutions, Japan remains a key market for advanced predictive maintenance technologies.

India: High-Growth Potential

India is expected to record a 7.4% CAGR, driven by rapid industrialization, infrastructure development, and the adoption of smart maintenance strategies. The country’s power generation, automotive, and transportation industries are key contributors to the rising demand for condition monitoring systems. Government initiatives promoting Make in India and smart manufacturing are further accelerating market growth.

Browse Report Details! https://www.futuremarketinsights.com/reports/condition-monitoring-system-market

Key Takeaways from Report:

- The Condition Monitoring System Market is expected to grow from USD 4,380.0 Million in 2025 to USD 9,196.7 Million by 2035, at a 7.7% CAGR.

- Increased adoption across industries such as manufacturing, energy, transportation, and aerospace due to the growing need for predictive maintenance.

- Vibration monitoring is the most widely used technique due to its effectiveness in detecting mechanical failures, particularly in rotating machinery, motors, and turbines.

- The rise of cloud-based and AI-powered remote condition monitoring solutions is reducing dependency on physical inspections, improving efficiency.

“The Condition Monitoring System Market is experiencing strong growth as industries prioritize predictive maintenance to reduce downtime and enhance operational efficiency. The adoption of AI-driven remote monitoring solutions is transforming asset management, particularly in manufacturing, energy, and transportation. With Industry 4.0 advancements and rising industrial automation, the market is poised for sustained expansion through 2035.” - opines Nikhil Kaitwade, Associate Vice President at Future Market Insights (FMI).

What is the Commercial Potential of Condition Monitoring System?

The power generation application segment has risen in the past couple of years due to stringent regulations to encourage emission control among various manufacturing plants that still use fossil fuels.

Power generation is becoming highly important nowadays as nations are seeking sustainable development through renewable sources. Power generation plants are very essential, which is why many industry leaders are turning towards condition monitoring systems to ensure that the machinery is unaffected by power cuts and the major components remain intact and safe. Moreover, manufacturers are providing durable sensors and systems to endure the harsh environmental conditions in which the power generation equipment are used.

Tougher regulatory and safety requirements coupled with the aging workforce in industries across various countries are encouraging adoption of condition monitoring systems. With increasing use of machinery equipment and components, focus on protecting them against wear and tear is increasing. Condition monitoring systems allow to identify machinery parts and components that either need repair or change.

Industrial facility managers are continuously working on improving maintenance processes at manufacturing plants. It is crucial to gain insights pertaining to the same to capitalize on the benefits of data-enabled predictive maintenance. With predictive maintenance, facility managers can avoid virtual downtime when an equipment is not operating to its maximum potential.

Condition monitoring systems can leverage a range of data, which includes equipment run time, energy usage, temperature, output, and others, to improve decision making and operations at manufacturing plants or at manufacturing units. This is expected to lead to the adoption of condition monitoring solutions at facilities.

Key Players Operating in the Market:

- Emerson Electric Co.

- General Electric Company (GE)

- ABB Ltd.

- Schneider Electric SE

- Siemens AG

- Honeywell International Inc.

- SKF Group

- National Instruments Corporation

- Parker Hannifin Corporation

- Rockwell Automation, Inc.

Explore the Latest Trends in Responsible Resource Management & Safety – Click to Stay Informed! https://www.futuremarketinsights.com/industry-analysis/responsible-resource-management-and-safety

Condition Monitoring System Industry Segmentation Analysis:

By Product Type:

- Corrosion Monitoring

- Infrared Thermography

- Motor Condition Monitoring

- Oil Analysis

- Ultrasound Testing

- Vibration Analysis

By End-Use Industry:

- Power Generation

- Oil & Gas

- Automotive & Transportation

- Aerospace & Defense

- Metals & Mining

- Chemical & Petrochemical

By Region:

- North America

- Latin America

- Western Europe

- Eastern Europe

- East Asia

- South Asia

- Middle East & Africa (MEA)

About Future Market Insights (FMI) – Industrial Automation:

The industrial automation division of Future Market Insights (FMI) offers a novel approach and innovative perspective in analyzing the industrial automation market. Comprehensive coverage of capital, portable, process, construction, industrial, and special-purpose machinery across the manufacturing sector and distinctive analysis of the installed base, consumables, replacement, and USP-feature-application matrix make us a pioneering voice in the industry. We are preferred associates with established as well as budding industry stakeholders and channel partners when it comes to sustaining, growing, and identifying new revenue prospects.

Explore Future Market Insights, Inc. Extensive Coverage in Industrial Automation Domain:

The tire inspection system market size to cross USD 287.4 Million by 2034.

The global testing, inspection, and certification market revenue to exceed USD 4,18,640.80 Million by 2033.

The global machine tool touch probe market share to hit USD 659.61 Million value by 2033.

The industrial hearables market size forecasted to cross USD 1,700 Million by 2033.

The demand for military parachutes to rise at a CAGR of 5.5% during the forecast period 2023 to 2033.

The India electrical testing services market size to exceed USD 308.4 Million by 2033.

The global metal recycling equipment market forecasted to surpass USD 18 Billion by 2033.

The global compositing equipment market revenue to surpass USD 177 Million by 2033.

The United States Plastic-to-fuel industry projected to surpass USD 1,926.9 Million by 2033.

The global fire protection system for the industrial cooking market to hit USD 9.3 Billion by 2033.

About Future Market Insights (FMI):

Future Market Insights (FMI) is a leading provider of market intelligence and consulting services, serving clients in over 150 countries. FMI is headquartered in Dubai, and has delivery centers in the UK, U.S. and India. FMI's latest market research reports and market analysis help businesses navigate challenges and make critical decisions with confidence and clarity amidst breakneck competition. Our customized and syndicated market research reports deliver actionable insights that drive sustainable growth. A team of expert led analysts at FMI continuously tracks emerging trends and events in a broad range of industries to ensure that our clients prepare for the evolving needs of their consumers.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn | Twitter | Blogs | YouTube

Distribution channels: Book Publishing Industry ...

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release